Colibrì

The ultimate spinning ring solution for fine and super fine counts is now available thanks to COLIBRÌ, the product developed as requested by the most demanding customer.

Fine and super fine counts require a special ring surface to run at the maximum speed with lowest possible yarn breakages.

The COLIBRÌ ring obtains this result thanks to the combination of 75+ years experience of PROSINO-BORGOSESIA RINGS and the state of the art non metallic coating.

Traditional spinning rings require the so called “break-in” procedure that creates a steel tribo-oxidation.

The COLIBRÌ ring has a special non metallic dry lubrication coating that allows you to start the new ring at final speed without any long and unproductive running-in schedule

The COLIBRÌ ring can run successfully with any traveller available in the market thanks to its high adaptability coating.

Diffusion treated travellers are suggested to obtain the best results.

Technical features

The COLIBRÌ ring coating has a micro-crystalline structure that gives the following advantages:

Extreme high coating uniformity, better than any other ring coating in the market.

COLIBRÌ – FINE COUNTS SPUN EASILY

APPLICATION RANGE

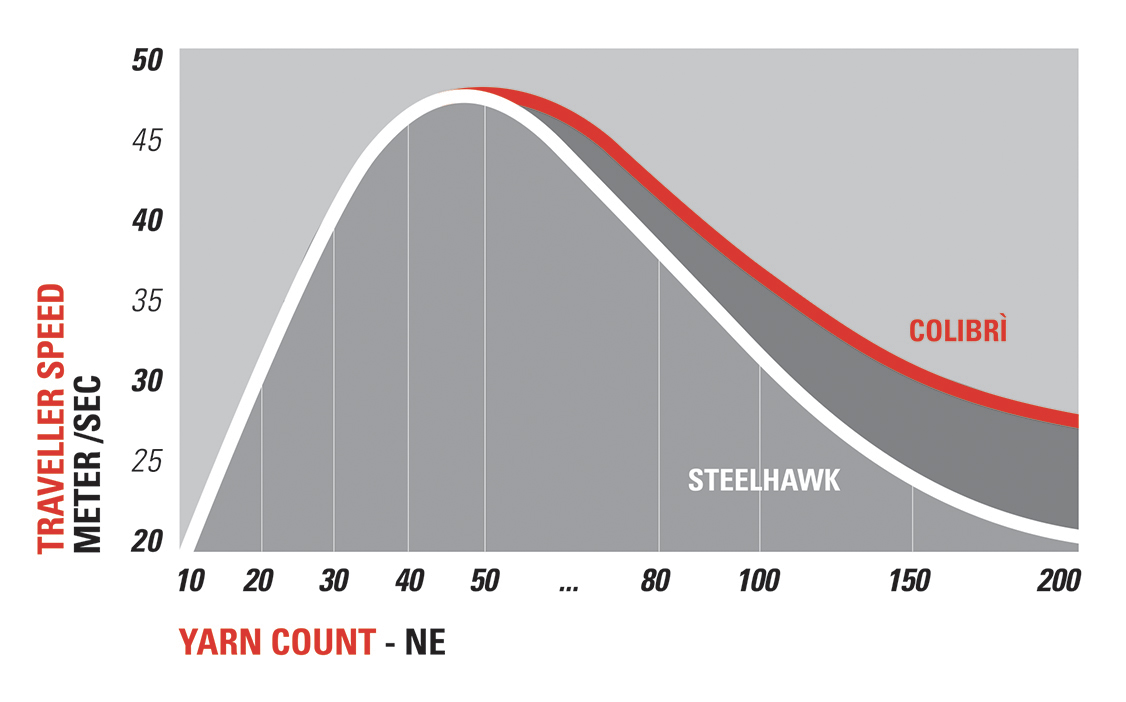

COLIBRI rings allow to reach proportionally higher speed with fine and super fine counts thanks to its special micro-crystalline structure.

SUPERIOR SPEED and 1st CLASS CONSISTENCY

HIGH WORKING SPEED VALUE

High working speed can be reached with COLIBRI’ spinning ring thanks to the following factors:

Low roughness (less than 0,2 µRA);

Ultra precise flange profile achieved thanks to the unique PROSINO form turning technology;

Dry lubrification anti wear coating;

Very high consistency of all mechanical parameters (out-of-roundeness, hardness, roughness).

OUTSTANDING YARN QUALITY

EVERLAST COATING

COLIBRI’ spinning ring helps the reduction of hairness providing a smooth surface for a long period of time on all spindle positions;

Hairiness, among its several sources, has its root cause on the dimension of spinning triangle. The area of the spinning triangle change over time due to change in yarn tension, which is strongly influenced by the coefficient of friction between ring and traveller. When the ring surface is worn out (see picture), the coefficient of friction changes;

COLIBRI’ ring, thanks to special non metallic dry lubrication coating keep its smoothness over the years, giving a significant contribution to the control of yarn tension, spinning triangle and ultimate yarn hairiness.

The COLIBRÌ ring coating has a micro-crystalline structure that gives the following advantages: longer traveller life, fiber catching surface and extreme high coating uniformity, better than any other ring coating in the market.

RAW MATERIAL AND HEAT TREATMENT

THE BEST CORE STRUCTURE

Made in high carbon, high chrome core hardened 100CR6 ball bearing steel, COLIBRI’ has been developed by using our 25 plus year of experience in the manufacturing of super precision and aerospace bearings. This products are produced for the most prestigious first class manufacturers such as SKF, FAG, INA and SNR-NTN;

The raw material used by PROSINO is an outstanding low sulfur, high purity steel that undergo the most challenging inspection before been released as “OK for production”. Heat treatment, thanks to subfreezing step allow the perfect over time dimensional stability.

TARGET OPERATION

The COLIBRÌ ring completes the product range of PROSINO-BORGOSESIA RINGS filling the gap in fine and super fine counts application.

Fine and super fine counts have a specific need when it comes to spinning rings: the traveller load is low, but the lubricating capacity of the fiber is very less.

The COLIBRÌ ring is able to retain the minimal lubrication given by the fiber mantaining a low coefficient of friction and a corrosion resistance surface.

PROUDLY WORKING FOR THE BEST BRANDS

We make the difference

When it comes to spinning and twisting rings, Prosino srl is the market leader with an yearly manufacturing of more than 9.000.000 rings and world market presence since 1946. Everywhere in the world the best spinners works with Prosino since they know that they can get customized products, top quality and fair prices directly from the manufacturer. The same care and dedication is put in the relationship with the most important bearing manufacturers worldwide, that have found in PROSINO outstanding quality, just-in-time deliveries, flexibility and technical competence.